Make Your Custom Glass Bottles

#1 Identifying Your Glass Bottle Idea

Whether we’re working from a sketch or we’re using a sample of another container, or just discussing your ideas, we will be working patiently with you to comprehend your exact requirements. Our design team will further investigate your requirements and not only generate ideas that suit your original brief, but will also take into consideration a feasible price as well as manufacturing alternatives and improvements to aid production and filling.

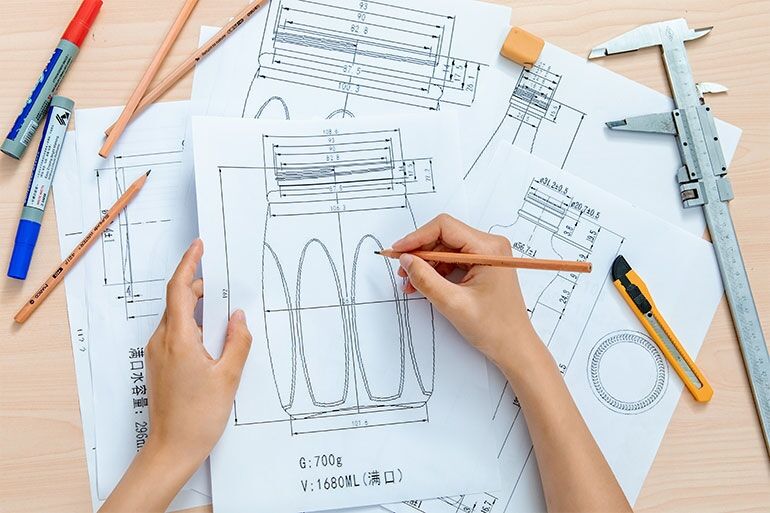

#2 Custom Glass Bottle Drawing

Once the design has been created, a bottle specification drawing is produced to define measurable features of the bottle, whilst observing the manufacturing limits. At this stage, we need to validate the technical specification prior to production.

Our cross-functional team of industrial designers and engineers is ready to assist with:

1.Bottle and closure design

2.Dispensing and dosing systems

3.Ergonomics and form factors

4.Rapid prototyping

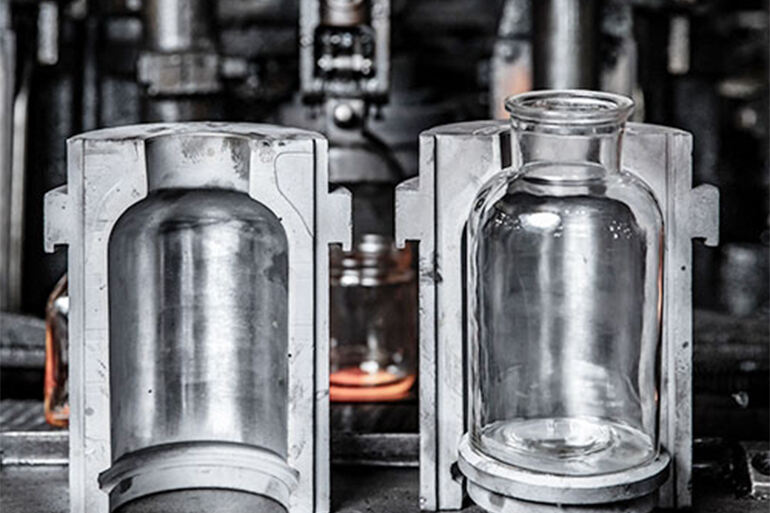

#3 Making Custom Glass Bottle Molds

Molds are the key to realizing your ideas in glass. Roetell’s aim is to offer a complete range of custom bottle molding and tooling services to match your required bottle shapes.With its ability to supply molds, neck rings, and any other components required for the molding process, Roetell is your one-stop shop for all your container molding needs.

#4 Processing Glass Bottle Sample

Once the trial mold equipment is received and a suitable production slot is confirmed, we proceed to manufacture glass bottle samples to ensure that we are happy with the production and that it meets your requirements.

You will have the opportunity to test the samples down your filling line, label them and check their compatibility with the closure and secondary packing, before giving formal approval to proceed to bulk production.

#5 Custom Glass Bottle Manufacturing and Packaging

The manufacturing process begins with treated raw materials being fed into a melting furnace. When the mixture is melted it’s put into molds. The ‘Blow and Blow’ or ‘Press and Blow’ formation methods are used to form the bottles. Our finishes include:

1.Short-necked

2.Long-necked

3.Balloon-like

4.Slender

5.Rounded

6.Cornered

After cooling, a rigorous quality inspection follows before careful packaging for delivery.